IAQ IQ, Winter/Spring 2023

©2023 Jeffrey C. May

Spray polyurethane foam (SPF) insulation is frequently used in new construction and in renovation projects.

In this article, I am raising two red flags about the use of this material.

- Odors can result from incorrect installations.

- SPF dust and non-adhering droplets can remain after SPF has been installed.

FOAMS

SPF is a foam. Foams are formed by trapping pockets of gas (“bubbles” or “cells”) in a liquid or solid. There are two types of foams: closed cell and open cell. In an open-cell foam, each bubble or cell is open to adjacent bubbles or cells, so liquids and gasses can move through an open-cell foam (though slowly in some open-cell foams). In a closed-cell foam, each bubble or cell is intact and is surrounded by other intact bubbles and cells, so there is no communication among them.

A sponge is an open-cell foam; tubular insulation at the exterior of piping is a closed-cell foam.

Depending on the components in the two parts, SPF insulation can be either open-cell or closed-cell foam. When solidified, open-cell SPF is crumbly and porous, and is an air barrier but not a vapor barrier. Open-cell SPF can be applied in a single application to a final depth of six or more inches. Closed-cell SPF is denser and quite hard, so neither air nor moisture can flow through it. If closed-cell SPF is to be more than about two inches thick, it must be installed in layers called “lifts.”

Whether open-cell or closed-cell, when SPF is formed, two things must happen: gas has to expand to form the bubbles, and the liquid between the bubbles has to solidify in order to contain the gas. SPF is formed by mixing together two different liquids, usually referred to as “Part A” and “Part B.” The two parts are heated, mixed together in a nozzle under high pressure, and then sprayed onto a surface. To facilitate the chemical reactions that occur when SPF is formed, a catalyst is needed.

ODORS FROM SPF INSTALLATIONS

If Parts A and B are not mixed together in the correct ratio or SPF is not installed under the recommended conditions, odors can result. The odors can be very irritating, and some of my clients report experiencing headaches and eye irritation when exposed to it. The odors caused by incorrectly installed open-cell SPF will off-gas over time (sometimes months); the odors caused by incorrectly installed closed-cell SPF can take even longer (sometimes years) to off-gas.

Odors from Closed-Cell SPF Installations

In its original formulations, a single closed-cell SPF lift was sometimes applied too thickly. Other times, each one of multiple lifts did not have time to cool sufficiently before another lift was applied. Then the foam would have started to overheat and decompose, resulting in odors.

Most catalysts in closed-cell SPF contain nitrogen. Many organic compounds (compounds that contain carbon) containing nitrogen belong to a class of organic compounds that are related to ammonia and that are called amines. Many amines have a strong, ammonia-like or dead-fish odor.

People who complain about the odor that SPF can emit usually note that the smell is much stronger when the sun is shining on the walls or the roof where the insulation is present. The odor can also be strong where the insulation is exposed, such as in an attic or in attic eaves.

Reducing the Odor of either Open-Cell or Closed-Cell SPF

Odiferous SPF can be covered with a paper-aluminum-foil laminate, which could stop off-gassing. Some people temporarily install a low-volume exhaust fan to depressurize an attic that has odiferous SPF insulation. Another option to reduce a dead-fish or ammonia odor would be to have the foam painted with a shellac-based paint, because shellac is an acid, and the dead-fish amine odor is a base (an acid and a base can neutralize each other). Sometimes, though, the SPF must be removed, and this can be an expensive venture. Fortunately, fewer than one in two hundred SPF jobs is associated with odor problems.

Some Case Studies of SPF Odors

In the last decade I’ve investigated a number of properties where SPF emitted such a strong odor that the insulation had to be removed. In one home with tongue-and-groove cathedral ceilings, the contractor had to remove all the roof shingles and sheathing to remove and replace the insulation. In another home, SPF had been sprayed against a foundation wall in what became a fully finished basement. In order to remove the foam, all finished wall materials had to be torn away and the finished basement entirely rebuilt.

Sometimes people just give up and move out of a property with odiferous SPF. One family had built a dream home in Florida. SPF was installed in all the exterior walls and in the attic. The resulting odor was so strong that they moved out of the house with only the clothes on their backs, leaving all their belongings and even food in their refrigerator.

But the odors that can result from some SPF installations are not my only concern.

SPF DUST AND UNADHERED DROPLETS

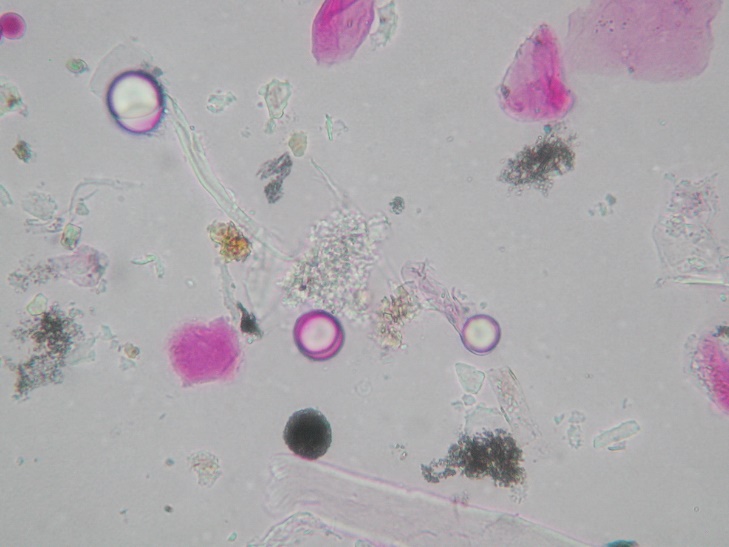

In an IAQ IQ newsletter I wrote twelve years ago, I expressed concerns about the odors that can result from incorrectly installed SPF installations. Since then, I have seen dozens of open-cell and closed-cell SPF installations on foundation walls, in attics, and in attic eaves in which SPF overspray and dust remain on many surfaces, which raises my concerns about the health implications of some SPF insulation.

.

Some SPF dust can be aerosolized when disturbed and then come in contact with skin or even be inhaled. The dust and non-adhered droplets contain the chemicals that are in the foam. These chemicals include isocyanates (in Part A) and flame retardants (in Part B).

Isocyanates: These chemicals are highly toxic and yet are used in “the manufacture of flexible and rigid foams, fibers, coatings such as paints and varnishes, and elastomers, and are increasingly used in the automobile industry, auto-body repair, and building insulation materials.” The Centers for Disease Control and Prevention (CDC) report that installers exposed to these chemicals can experience eye irritation, digestive problems, and respiratory symptoms including severe asthma, coughing, and skin irritation.1

Fortunately, all of the isocyanates in Part A react (combine) almost instantly with the chemicals in Part B. Any residual isocyanates react very quickly with moisture in the air. Building occupants therefore have very little or no risk of exposure to isocyanates.

Flame retardants, however, are another story.

Flame Retardants: In 2003, a bulk-type of foam insulation had been attached to the ceiling for soundproofing in The Station nightclub in West Warwick, RI. The foam did not contain flame retardants and thus caught on fire when the band used fireworks indoors in the act. Nearly a third of the people in the nightclub were unable to exit the building, and more than 100 people died and 200-plus more were injured.2 Had the foam contained flame-retardant, this disaster might not have occurred.

But concern has grown about the use of flame retardants in manufactured goods. California has a law (AB 2998) that prohibits the sale after January 1, 2020 “of juvenile products, upholstered furniture, replacement components of reupholstered furniture, and the foam in mattresses (collectively referred to as ‘covered products’) that contain … flame-retardant (FR) chemicals at levels above 1,000 parts per million (ppm).”3 The American Chemical Society’s publication, Chemical and Engineering News, reported that “A new law in New York State bans the sale of televisions and other electronic displays that contain any intentionally added organohalogen flame retardant in their plastic enclosures or stands. Scientific studies link exposure to organohalogen flame retardants to cancer, hormone disruption, and reproductive problems, as well as neurological injury in children.”4

Some research has been done on the potential deleterious health effects of SPF installations – effects on both installers and building occupants alike.5 More research needs to be done, however.

CAUTIONS ABOUT SPF INSTALLATIONS

The following cautions should have been exercised when SPF was installed:

- All building occupants should be absent from the building when the material is being installed and for whatever length of time afterwards as is recommended.

- Part A and Part B should be mixed together at the correct temperature and pressure and in the correct ratio.

- The material should be installed under the recommended conditions.

- Mechanical-systems in the area should be turned off, closed, and covered during the installation.

In addition, I recommend that:

- Ideally, anything accessible that was in an attic or attic eaves, such as flooring and ductwork, should have been temporarily covered with thin plastic to minimize SPF overspray and dust from collecting on or adhering to surfaces.

- If the foam was installed in a basement, efforts should have been made to prevent the accumulation of SPF dust and overspray on surfaces.

- Wherever and whenever the foam was installed, any remaining SPF dust and non-adhering SPF droplets should have been HEPA vacuumed away.

on this access panel for the blower cabinet in an air handling unit.

If you have any concerns about an SPF installation in a building you are inspecting, your client could find out what company did the installation and whether the company had been installing SPF for at least five years. You client could also confer with an SPF consultant (see “Resources”).

SPF is an excellent insulation; we just don’t want it to pose a health risk.

Resource:

For SPF consultants, go to the Spray Polyurethane Foam Alliance (SPFA) website:

https://www.sprayfoam.org/custom_Directory.asp. Enter “Consulting Services” in “Directory Category.”

There is an SPF consultant in Vermont who inspects as well as oversees SPF installations and who travels: Henri Fennell, H C Fennell Consulting, LLC, 802-222-7740, hfennell09@gmail.com, https://polyurethanefoamconsulting.com.

End Notes:

- Centers for Disease Control and Prevention, https://www.cdc.gov/niosh/topics/isocyanates/default.html.

- https://www.thesunchronicle.com/news/news_updates/foam-company-offers-station-nightclub-fire-plaintiffs-6-3m-settlement/article_475f84de-fe7d-5f1f-a2a6-3dffc6135deb.html

- https://bhgs.dca.ca.gov/forms_pubs/ab2998_faq.pdf)

- Chemical & Engineering News, “Consumer Safety,” January 10/17, 2022, page 15.

- “Exposure to organophosphate flame retardants in spray polyurethane foam applicators: role of dermal exposure,” Moria Espina et al., Environ Int. 2018 Jan;110:32-41. doi: 0.1016/j.envint.2017.10.001. Epub 2017 Nov 6. National Library of Medicine, https://pubmed.ncbi.nlm.nih.gov/29102155/.

“Assessment and control of exposures to polymeric methylene diphenyl diisocyanate (pMDI) in spray polyurethane foam applicators,” Anila Bello et al., Int J Hyg Environ Health. 2019 Jun; 222(5):804-815. doi: 10.1016/j.ijheh.2019.04.014. Epub 2019 May 8. National Library of Medicine, https://pubmed.ncbi.nlm.nih.gov/31076286/.

Unless otherwise indicated, the photographs and micrograph in this article are the property of May Indoor Air Investigations LLC and cannot be used without permission.

Our latest book on indoor air quality, My House is Killing Me! A Complete Guide to a Healthier Indoor Environment, was published in December 2020 and is available on line. A discussion on the pros and cons of SPF insulation is on pages 313-317.